End Suction Pump

End suction pump IHF series (F46 inner layer)

- Flow: 2 - 1,100 m3/h

- Delivery Head: 5 - 125m

- Outlet Dia.: 32 - 250mm

- Liquid pH Value.: 1-14

- Product description: End suction pump, Acid-Proof pump, anti-corrosive pump, acid transferring pump

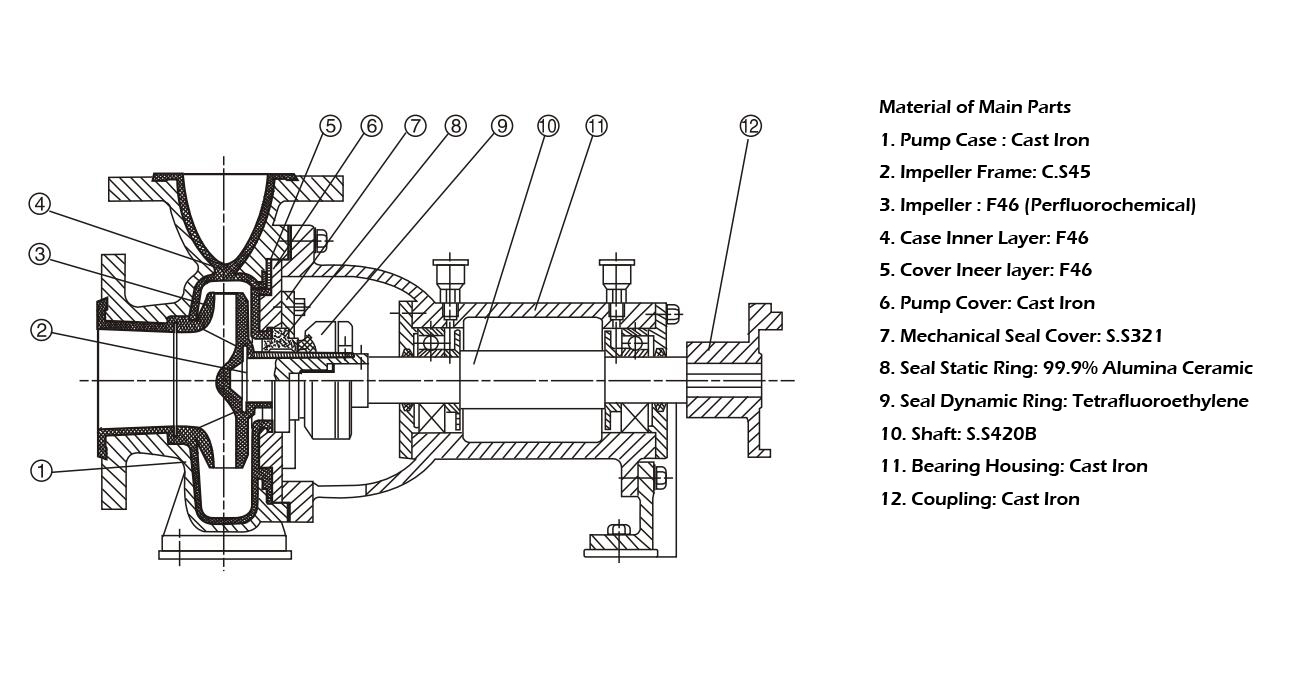

IHF single stage single suction acid-proof centrifugal pump (IHF chemical centrifugal pump) is designed and manufactured according to ISO5828 and combined with non-metallic pump technology. The pump body is made of metal shell lining polyfluorinated ethylene propylene (F46). The pump cover, impeller and bushing are all made of metal inserts outside the fluoroplastic sinter pressed, the shaft seal adopts externally mounted advanced bellows mechanical seal, static The ring is made of 99.9% aluminum oxide ceramic (or silicon nitride), and the moving ring is made of PTFE filling material, which has excellent corrosion resistance and wear resistance. The inlet and outlet of the pump are all reinforced with cast steel to enhance the pressure resistance of the pump. The actual use shows that the pump has the advantages of corrosion resistance, wear resistance, high temperature resistance, no aging, high mechanical strength, stable operation, advanced and reasonable structure, strict and reliable sealing performance, convenient disassembly and overhaul, and long service life.

Design Features

1. IHF acid-proof centrifugal pumps are designed and manufactured in accordance with international standards in accordance with international standards. Its performance, rated performance points and dimensions are equivalent to the relevant international standards and national standards:

2. IHF acid-proof pump body and the pump cover are made of a metal-based body lined with fluoroplastics, and the impeller is molded with a dedicated mold in the metal insert outsourcing fluoroplastic alloy;

3, a wide range of corrosion resistance, high strength and durability;

4. The shaft seal adopts advanced exterior-type bellows mechanical seal, and the world-advanced SSIC industrial ceramics are used for the moving and stationary ring of the grinding, and other materials can also be used according to the user’s special working conditions to grind the material.

5, corrosion resistance, wear resistance, sealing, easy installation, easy maintenance.

Design Features

1. IHF acid-proof centrifugal pumps are designed and manufactured in accordance with international standards in accordance with international standards. Its performance, rated performance points and dimensions are equivalent to the relevant international standards and national standards:

2. IHF acid-proof pump body and the pump cover are made of a metal-based body lined with fluoroplastics, and the impeller is molded with a dedicated mold in the metal insert outsourcing fluoroplastic alloy;

3, a wide range of corrosion resistance, high strength and durability;

4. The shaft seal adopts advanced exterior-type bellows mechanical seal, and the world-advanced SSIC industrial ceramics are used for the moving and stationary ring of the grinding, and other materials can also be used according to the user’s special working conditions to grind the material.

5, corrosion resistance, wear resistance, sealing, easy installation, easy maintenance.

Main Performance Data

Flow: 2 - 1100 m3/h

Delivery Head: 5 - 125m

Outlet Dia.: 32 - 250mm

Working Pressure: ≤ 1.5Mpa

Solid Particle: ≤ 80mg/L

Liquid Temp.: -20℃ - 150℃

Model Instruction

E.G.: IHF100-80-160A

IHF: Acid-Proof single stage end suction pump

100: Inlet diameter is 100mm

80: Outlet diameter is 80mm

160: Rate impeller diameter is 160mm

A(B,C....): Impeller code

Applications

Acid liquid transferring,

Chemical liquid transferring,

Sea water desalination & transferring,

Fibre processing industry, Paper & pulp industry,

Soda industry

The pump could be applied to transfer different kinds of liquid by customized wet parts, here followed our recommendation of main configuration:

Categories

Contact Us

Contact: Johnson Long

Phone: +86-13100332518

Tel: +86-731-86671018

Add: No.999, Guitang Road, Yuhua District, Changsha City, Hunan Province, China.